Markus Bauinger

Sales ManagerTel: +43 720 569-122

Mobil: +43 664 831 6867

Fax: +43 720 569-101

E-Mail: bmk@gautschi.cc

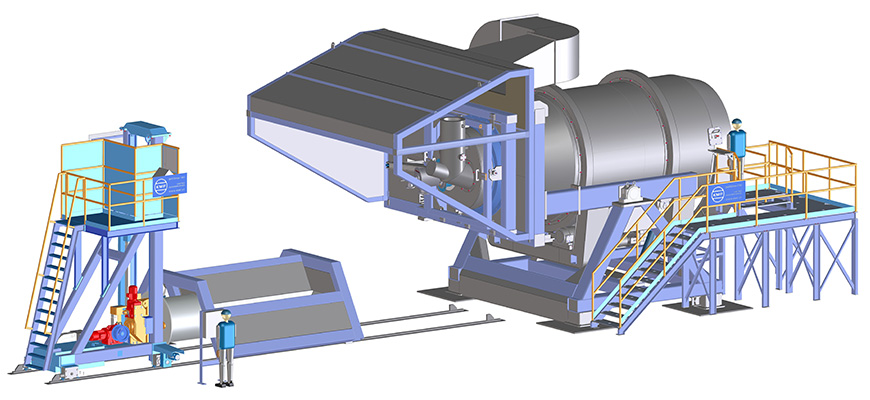

Tilting Rotary Furnaces MASTERmax

The world wide bench mark for high yield and free choice of slag technologyThe MASTERmax with capacities from 5 to 30 t offers fully automatic recycling solutions and ensures repeatable results, particularly with organically contaminated scraps.

Low salt technology as well as melting of thin walled scraps under liquid salt are possible in the hybrid furnace.

The MASTERmax accordingly is world wide the only tilting rotary furnace granting the classical liquid as well as the salt saving low salt Technology.

|

Type |

Capacity |

Charge weight |

Net melt rate* |

Cycles |

Throughput |

|

1TR2 |

2,0-5,0 |

1,0-1,5 |

Up to 2,0 |

5-8 |

3-5 |

|

2TR5 |

5,0-10,0 |

1,5-2,0 |

2,8-3,4 |

5-7 |

6-10 |

|

3TR9 |

9,0-19,0 |

1,5-2,5 |

4,2-5,0 |

5-6 |

9-15 |

|

4TR12 |

12,0-30,0 |

2,5-4,0 |

5,6-7,0 |

4-5 |

15-25 |

*) Valid for oxyfuel burners only, with gas/air the figures are 30 – 40% lower.

Spezifications

- Types 1TR2, 2TR5, 3TR9 and 4TR12

- Hydraulic tilting rotary furnace with solid base frame

- Horizontal converter tilting from -8° to +22°

- Travelling high speed, low noise charging machine with rotating shovel, suitable for any shape of scrap

- For processing of all kind of aluminum scraps including contaminated ones and dross

- Double pass burner system

Function

- Automatic, extremely rapid charging

- Smoldering and burning of organics within the furnace

- If required, oxygen injection to assist burning of organics with air burners

- Minimized oxygen content in the furnace during melting for reduced oxidation loss

- Tapping by means of valve with closed door

- Discharge of slag through the doors

Advantages of the MASTERmax

- Large volume for burning of the organics within the furnace

- Higher organic contents hence acceptable

- Additional energy recovery by means of burning the organics within the furnace

- Permanent high yield by low grade scraps

- High productivity due to extremely short charging times

- Switching from low to liquid salt process possible to optimize yield

- PLC process control by means of MELTmax software

- Permanent process control

- Display of parameters (weight, temperatures, gas- and oxygen consumption)

- Visualized product data acquisition (PDA)

- Variable converter rotation throughout the entire cycle

- Environmental friendly combustion of the smoldering gases within the furnace

- Low energy consumption and emissions due to double pass burner system

- Use of proven refractories for long lining live

- High plant and operation safety due to innovative engineering

- Easy handling due to automated sequences

Markus Bauinger

Sales ManagerTel: +43 720 569-122

Mobil: +43 664 831 6867

Fax: +43 720 569-101

E-Mail: bmk@gautschi.cc