Markus Bauinger

Sales ManagerTel: +43 720 569-122

Mobil: +43 664 831 6867

Fax: +43 720 569-101

E-Mail: bmk@gautschi.cc

Dross Cooling COOLmax

COOLmax 500 (PATENT PENDING)Our newly developed COOLmax 500 is capable to save precious Aluminium in-house by cooling down either Al-rich dross from reverbatory furnaces or dry salt slag from tilting rotary furnaces. The COOLmax can roughly process 500kg per hour and can be placed nearby the furnaces to minimize the time before the cooling starts. The main components of our COOLmax 500 are fan, vertical exhaust, motor, control unit and aircooled double-walled cooling mechanism and dross/slag container.

General description of COOLmax 500

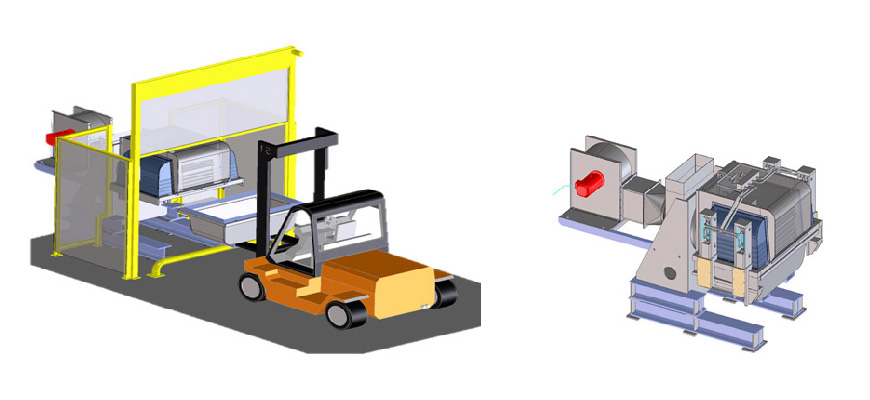

Hot dross from reverbatory furnaces or dry salt slag from Tilting Rotary Furnaces can be filled directly into the COOLmax dross/slag bin.

The bin will be instantly transported by a forklift to the COOLmax which is preferably nearby the furnaces. After the dross/slag container has been connected by hydraulic force to the COOLmax, the machine starts to cool down the dross/slag via a patented system of aircooling and milling.

After the combined cooling of less than 1h below 350°C and milling the residuals can be sieved and the aluminium can be used for most efficient inhouse recycling.

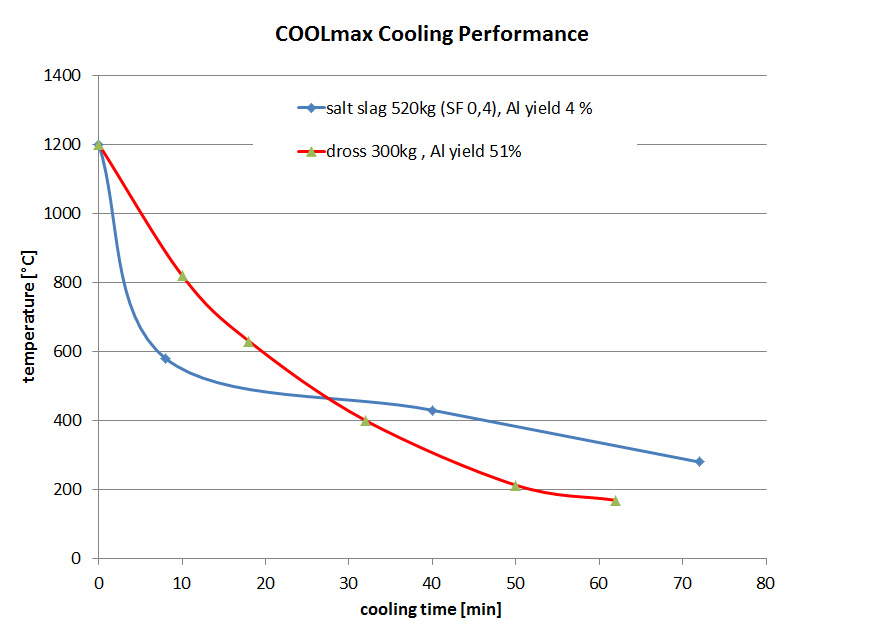

COOLmax Performance Data

Cooling rate can vary a bit depending on dross/slag composition and temperature

Technical Data

Capacity: 0,5 t

Weight of cooling container: 1 t

Various fractions of recovered Aluminium after ca. 60 min of COOLmax Treatment

Dimensions Dross/slag container: 1500 x 800 x 500 (LxBxH)

Air flow (vertical exhaust direction). 13m³/sec

Electrical power: 18 kW (400V, 32A)

Dimensions : 2,0 x 1,7 x 1,6 m (LxBxH)

Total Weight: ca. 6 t

Sieve insert for simplified sieving

The sieve insert with approx. 10 mm mesh size can be inserted into the COOLmax after cooling. The finer aluminum fraction can be easily removed from the sieve insert after sieving.

Markus Bauinger

Sales ManagerTel: +43 720 569-122

Mobil: +43 664 831 6867

Fax: +43 720 569-101

E-Mail: bmk@gautschi.cc